The Role of Reverse Engineering Services in Product Innovation

- Sep 22, 2025

- 5 min read

In today’s fast-paced market, innovation is the key to staying competitive. Companies constantly seek ways to improve their products, reduce costs, and accelerate development cycles. One powerful tool that supports these goals is reverse engineering analysis. This process involves deconstructing a product to understand its design, components, and functionality. By doing so, businesses can gain valuable insights that drive innovation and enhance product development.

Understanding Reverse Engineering Analysis

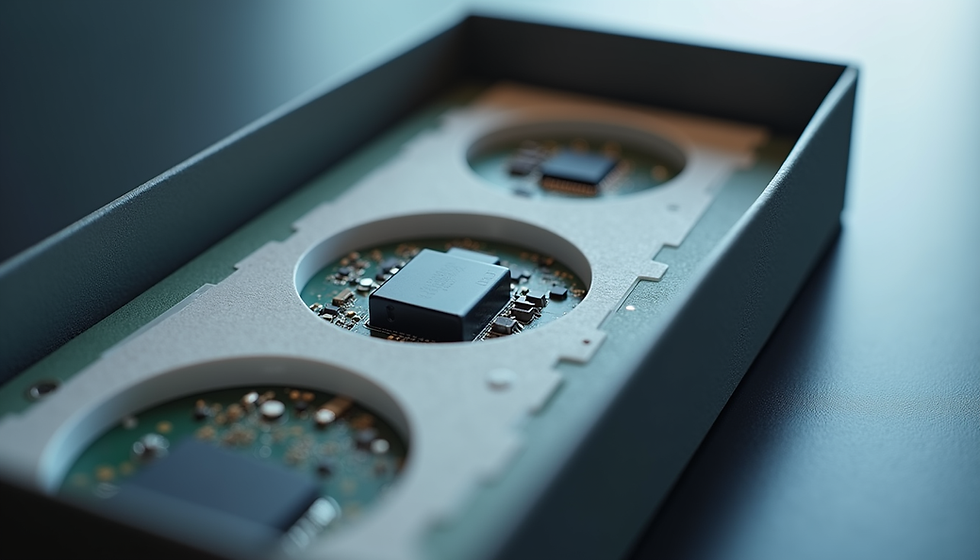

Reverse engineering analysis is the systematic examination of an existing product to uncover its underlying structure and operation. This process can involve physical disassembly, digital scanning, or software decompilation, depending on the product type. The goal is to extract detailed information that can be used to replicate, improve, or innovate upon the original design.

For example, a company might reverse engineer a competitor’s device to identify strengths and weaknesses. This knowledge can then inform the design of a new product that offers better performance or lower manufacturing costs. Additionally, reverse engineering can help in creating compatible parts or updating legacy products without original design documents.

Key Benefits of Reverse Engineering Analysis

Accelerates product development by providing a clear understanding of existing designs.

Reduces costs by identifying cheaper materials or manufacturing methods.

Enhances product quality through detailed analysis of successful features.

Supports compliance and safety by verifying product specifications.

Enables innovation by inspiring new ideas based on existing technologies.

How Reverse Engineering Analysis Drives Product Innovation

Reverse engineering analysis plays a crucial role in product innovation by offering a practical way to learn from existing products. Here are some ways it contributes to innovation:

1. Identifying Design Flaws and Opportunities

By dissecting a product, engineers can spot design flaws that may not be obvious from the outside. This insight allows them to improve durability, functionality, or user experience in the next iteration. For instance, reverse engineering a smartphone might reveal overheating issues caused by poor heat dissipation, prompting a redesign with better cooling solutions.

2. Enhancing Product Features

Reverse engineering can uncover hidden features or clever engineering solutions that competitors use. These discoveries can inspire new features or improvements in your own products. For example, analyzing a high-end camera lens might reveal unique coatings or materials that improve image quality, which can then be adapted for your designs.

3. Facilitating Customization and Adaptation

Sometimes, products need to be customized for specific markets or applications. Reverse engineering analysis helps by providing detailed knowledge of the original product, making it easier to modify or adapt components without starting from scratch.

4. Supporting Sustainable Innovation

Reverse engineering can contribute to sustainability by enabling the reuse of parts or materials. Companies can analyze products to find ways to recycle components or design for easier disassembly, reducing environmental impact.

5. Accelerating Prototyping and Testing

With detailed reverse engineering data, prototyping becomes faster and more accurate. Engineers can create digital models or physical prototypes that closely match the original, allowing for quicker testing and iteration.

One practical way companies access these benefits is through professional reverse engineering services, which provide expert analysis and detailed reports to guide innovation efforts.

Is Reverse Engineering Illegal in the US?

A common question about reverse engineering is its legality, especially in the United States. The answer depends on the context and how the information obtained is used.

Legal Framework

In the US, reverse engineering is generally legal when done for legitimate purposes such as:

Interoperability: Understanding how to make products work together.

Research and development: Improving or innovating products.

Security analysis: Identifying vulnerabilities.

Education: Learning and teaching purposes.

However, there are important legal boundaries:

Copyright and patent laws: Reverse engineering cannot be used to copy patented or copyrighted designs for direct resale or infringement.

Trade secrets: If the product is protected by trade secret laws, unauthorized reverse engineering may be illegal.

End User License Agreements (EULAs): Some software or hardware products include agreements that restrict reverse engineering.

Fair Use and Exceptions

US courts have recognized fair use exceptions that allow reverse engineering in certain cases, especially when it promotes competition or innovation. For example, reverse engineering software to create compatible products is often permitted.

Best Practices to Stay Legal

Always review applicable laws and agreements before starting reverse engineering.

Use the information obtained to create original or improved products, not to copy.

Consult legal experts if unsure about specific cases.

Understanding these legal nuances is essential for companies to leverage reverse engineering analysis without risking infringement.

Practical Applications of Reverse Engineering Analysis in Various Industries

Reverse engineering analysis is widely used across many industries to foster innovation and improve products. Here are some notable examples:

Automotive Industry

Car manufacturers use reverse engineering to analyze competitor vehicles, improve safety features, and develop aftermarket parts. For instance, reverse engineering a braking system can help design more efficient or cost-effective alternatives.

Aerospace

In aerospace, reverse engineering helps maintain and upgrade legacy aircraft by recreating parts that are no longer manufactured. It also supports the development of new components with enhanced performance.

Electronics and Consumer Goods

Electronics companies reverse engineer devices to understand circuit designs, improve battery life, or enhance user interfaces. This process accelerates innovation in smartphones, wearables, and home appliances.

Medical Devices

Reverse engineering is critical in medical technology for replicating or improving prosthetics, surgical tools, and diagnostic equipment. It ensures compatibility and safety while driving innovation.

Manufacturing and Tooling

Manufacturers use reverse engineering to create molds, dies, and tooling for production. This approach reduces lead times and costs by accurately replicating complex parts.

Tips for Leveraging Reverse Engineering Analysis Effectively

To maximize the benefits of reverse engineering analysis, consider the following recommendations:

Define clear objectives: Know what you want to achieve, whether it’s improving a product, reducing costs, or understanding competitor technology.

Choose the right tools: Use advanced scanning, CAD software, and analysis tools to capture accurate data.

Work with experts: Partner with professional reverse engineering services to ensure thorough and reliable analysis.

Respect legal boundaries: Always verify compliance with intellectual property laws and agreements.

Integrate findings into development: Use the insights gained to inform design, prototyping, and testing phases.

Document everything: Maintain detailed records of the reverse engineering process for future reference and quality control.

By following these steps, companies can turn reverse engineering analysis into a strategic advantage.

Embracing Reverse Engineering Analysis for Future Growth

Reverse engineering analysis is more than just a technical process - it is a catalyst for innovation. It empowers companies to learn from existing products, uncover hidden opportunities, and create better solutions. As technology evolves, the role of reverse engineering will only grow in importance, helping businesses stay ahead in competitive markets.

Investing in professional reverse engineering analysis and integrating it into your product development strategy can unlock new possibilities. Whether you aim to enhance product features, reduce costs, or enter new markets, this approach provides a solid foundation for success.

Innovation thrives on knowledge, and reverse engineering analysis is a powerful way to gain that knowledge. Embrace it to drive your products forward and shape the future of your industry.

Comments