Is PETG The Goldilocks of Filament for 3D Printing?

- Jun 24, 2025

- 4 min read

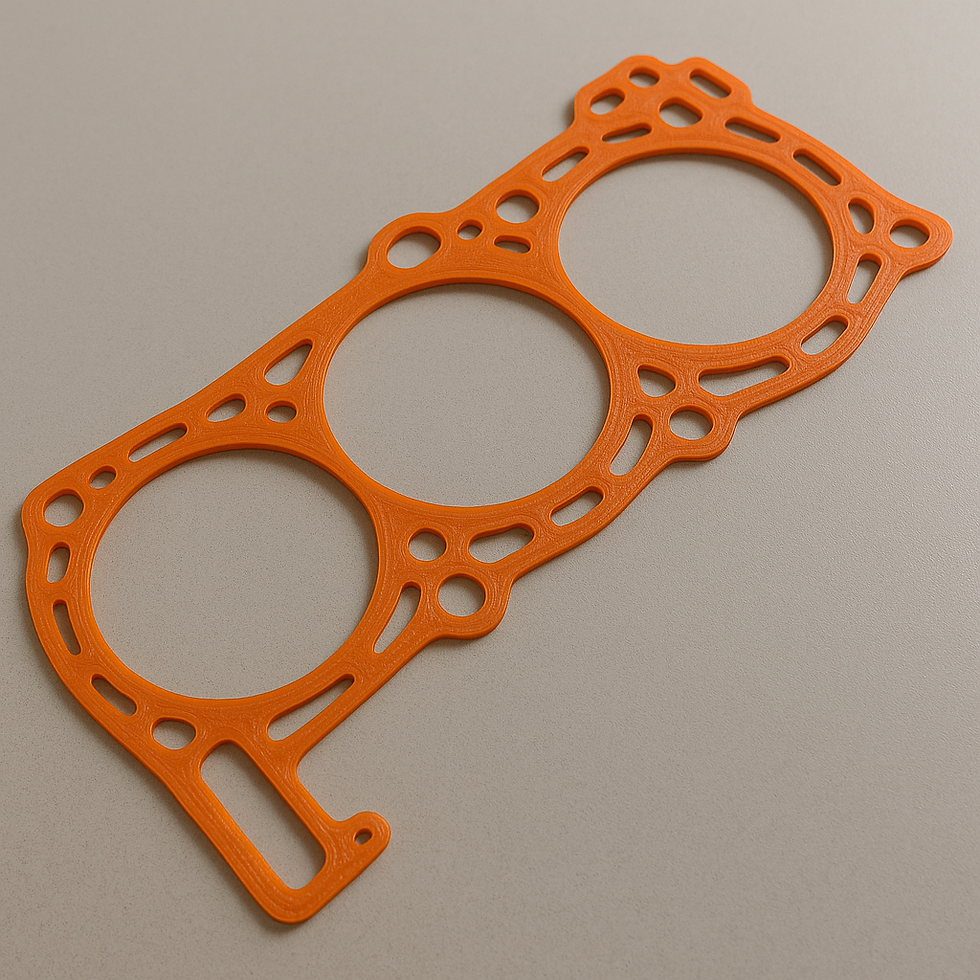

In the ever-expanding universe of 3D printing, choosing the right filament can feel like navigating a cosmic labyrinth. While PLA offers ease and ABS delivers strength, there's a material that strikes a remarkable balance: PETG. Polyethylene Terephthalate Glycol-modified, or PETG, has rapidly gained popularity as a versatile and reliable filament, offering the best of both worlds for many makers.

What Makes PETG So Special? A Detailed Comparison

To truly appreciate PETG, let's pit it against its common counterparts: PLA, ABS, and TPU.

Feature / Material | PLA (Polylactic Acid) | ABS (Acrylonitrile Butadiene Styrene) | PETG (Polyethylene Terephthalate Glycol) | TPU (Thermoplastic Polyurethane) |

Ease of Printing | Very Easy | Challenging (Warping, Fumes) | Moderate (Prone to Stringing) | Moderate (Flexible, Tricky Extrusion) |

Strength & Durability | Good (Rigid, Brittle) | Excellent (Impact Resistant) | Very Good (Tough, Flexible) | Excellent (Highly Flexible, Impact Absorbing) |

Heat Resistance | Low (Deforms ~60°C) | High (Withstands ~100°C) | Good (Withstands ~70-85°C) | Low (Deforms ~60°C) |

Flexibility | Rigid | Rigid (Slightly more flexible than PLA) | Moderate (Slight bend before breaking) | Highly Flexible, Rubber-like |

Layer Adhesion | Good | Moderate | Excellent | Good |

Surface Finish | Smooth, often glossy | Matte, can be vapor smoothed | Semi-transparent to opaque, glossy | Varies, often matte |

Chemical Resistance | Low | Good | Excellent | Excellent |

UV Resistance | Low (Degrades) | Moderate (Can degrade) | Good | Moderate |

Odor/Fumes | Low odor, minimal VOCs | Strong odor, high VOCs (Styrene) | Low odor, minimal VOCs | Low odor |

Hygroscopic | Moderately | Yes | Yes (Can absorb moisture) | Yes |

Technical Specifications of PETG

Density: Approximately 1.27 g/cm3

Tensile Strength: 40−50 MPa (can be higher depending on brand and print orientation)

Flexural Strength: Around 70−80 MPa

Impact Strength (Charpy Unnotched): 10−22 kJ/m2 (significantly higher than PLA)

Glass Transition Temperature (Tg): 77−85∘C

Heat Deflection Temperature (HDT): 70−76∘C (at 0.45 MPa)

Melting Temperature: PETG is amorphous, so it doesn't have a sharp melting point like crystalline plastics. It typically softens and becomes extrudable in the range of 220−260∘C.

Recommended Nozzle Temperature: 230−250∘C

Recommended Bed Temperature: 70−90∘C

Where PETG Truly Shines: Use Cases

PETG's unique combination of properties makes it excel in several applications where other materials fall short:

Functional Prototypes and End-Use Parts: Its excellent strength, impact resistance, and slight flexibility make it ideal for parts that need to withstand stress and minor impacts, such as enclosures, brackets, gears, and snap-fit components.

Outdoor Applications: With good UV and chemical resistance, PETG is a strong contender for outdoor fixtures, planters, and components exposed to the elements.

Transparent and Translucent Prints: PETG naturally prints with a clear or semi-transparent finish, making it perfect for light diffusers, protective covers, or prototypes where visual clarity is desired.

Liquid Containers and Food-Safe Applications (with caveats): While PETG itself is often considered food-safe, the layered nature of 3D prints can harbor bacteria. For direct food contact, a food-safe coating (like epoxy) is recommended. However, for prototyping packaging or non-direct contact, its chemical resistance is a huge plus.

Mechanical Assemblies: Its combination of strength and slight flex allows for durable hinges, clips, and moving parts that won't easily break.

Challenges with Printing PETG and How to Solve Them

While PETG is a fantastic material, it does present some unique printing challenges:

Stringing and Oozing: PETG is notorious for leaving fine strings or "cobwebs" between printed parts.

Solution:

Optimize Retraction Settings: Increase retraction distance (e.g., 4−6mm for Bowden, 2−3mm for direct drive) and retraction speed (30−80mm/s). Experiment to find the sweet spot for your printer.

Lower Nozzle Temperature: Print at the lower end of the recommended temperature range (230−235∘C) while ensuring good layer adhesion.

Increase Travel Speed: Faster travel moves can reduce the time for filament to ooze.

Excessive Bed Adhesion (Sticking Too Well): PETG can bond aggressively to certain print surfaces, especially bare glass, potentially damaging the bed upon removal.

Solution:

Use a Release Agent: A thin layer of glue stick, hairspray, or painter's tape on the print bed acts as a sacrificial layer, allowing for easier part removal.

Textured PEI Sheet: Textured PEI build plates are often ideal for PETG, providing excellent adhesion during printing and easy release when cooled.

Increase Z-Offset: A slightly higher Z-offset for the first layer (0.02−0.06mm more than PLA/ABS) can prevent over-squishing and reduce adhesion issues.

Hygroscopic Nature (Moisture Absorption): PETG readily absorbs moisture from the air, leading to popping, bubbling, inconsistent extrusion, and weakened prints.

Solution:

Dry Your Filament: Store PETG in a dry box with desiccant. If you suspect it's absorbed moisture, dry it in a filament dryer or a convection oven (60−70∘C for several hours, typically 4−6 hours).

Blobs and Zits: Over-extrusion or inconsistent flow can lead to unsightly blobs on the print surface.

Solution:

Reduce Flow Rate: Calibrate your extruder's E-steps and then slightly reduce the flow rate in your slicer (e.g., 95−98%).

Optimize Cooling: While too much cooling can reduce layer adhesion, a moderate fan speed (30−50%) can help solidify layers faster and prevent blobs, especially for small features.

Print Slower: For intricate details, reducing overall print speed can improve surface quality.

Poor Layer Adhesion: While PETG generally has good layer adhesion, incorrect settings can lead to weak parts that delaminate.

Solution:

Ensure Proper Print Temperature: Printing too cold will result in weak layers.

Reduce Cooling Fan Speed: For maximum strength, especially on lower layers, minimize or disable the cooling fan for the first few layers, then use a moderate speed.

Dry Filament: Moist filament significantly impacts layer bonding.

Conclusion

PETG stands as a formidable contender in the 3D printing material landscape. Its blend of strength, flexibility, chemical resistance, and ease of printing (once calibrated) makes it an excellent choice for a vast array of functional and aesthetic applications. While it demands a bit more attention to detail in terms of print settings than PLA, the superior properties of PETG often make the extra effort well worth it, empowering you to create truly robust and resilient 3D prints. So, if you're looking to step up your 3D printing game beyond basic prototypes, give PETG a try – you might just find your new favorite filament!

Comments