Enhancing Industrial Design with 3D Prototyping Services

- Nov 10, 2025

- 5 min read

Industrial design is a complex process that requires precision, creativity, and efficiency. One of the most transformative tools in this field today is industrial 3D prototyping. This technology allows designers and engineers to create physical models of their concepts quickly and accurately. By using industrial 3D prototyping, companies can reduce development time, improve product quality, and save costs.

Industrial 3D prototyping bridges the gap between digital designs and real-world applications. It enables rapid iteration and testing, which is crucial for refining product features and functionality. This blog post explores how industrial 3D prototyping enhances the design process, the benefits it offers, and practical tips for integrating it into your workflow.

The Role of Industrial 3D Prototyping in Modern Design

Industrial 3D prototyping plays a pivotal role in transforming ideas into tangible products. Unlike traditional prototyping methods, which can be time-consuming and expensive, 3D prototyping offers speed and flexibility. Designers can create detailed models that accurately represent the final product’s form and function.

For example, automotive companies use industrial 3D prototyping to develop parts that must meet strict safety and performance standards. By printing prototypes, they can test aerodynamics, ergonomics, and assembly processes before committing to mass production. This reduces the risk of costly errors and accelerates the time to market.

Additionally, industrial 3D prototyping supports customization. Manufacturers can produce unique parts tailored to specific customer needs without the need for expensive molds or tooling. This capability is especially valuable in industries like aerospace, medical devices, and consumer electronics.

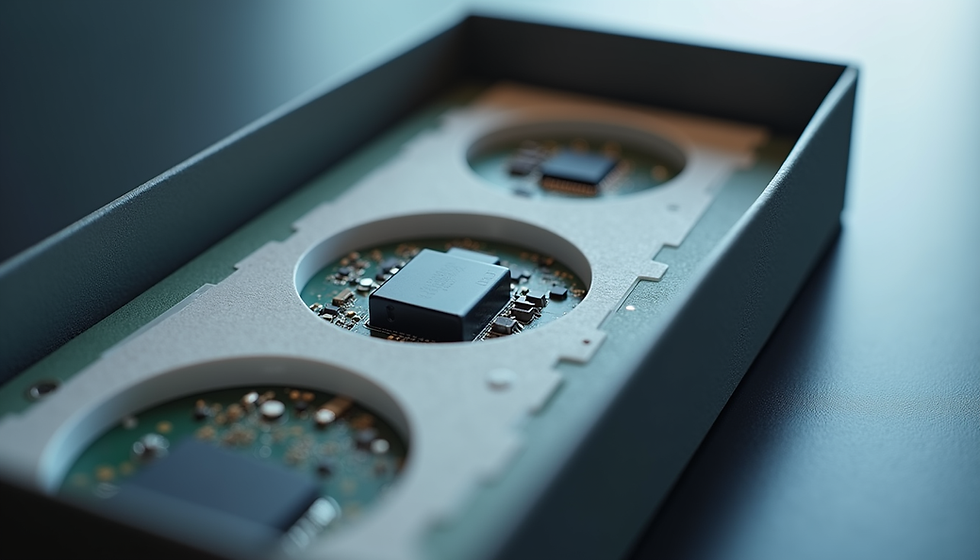

Close-up view of a 3D printed industrial prototype part showcasing detailed design features

Benefits of Industrial 3D Prototyping for Product Development

The advantages of industrial 3D prototyping extend beyond speed and cost savings. Here are some key benefits that make it an essential tool for product development:

Rapid Iteration: Designers can quickly produce multiple versions of a prototype, testing different materials, shapes, and mechanisms. This iterative process leads to better design decisions.

Improved Accuracy: 3D printing technology can achieve high precision, ensuring that prototypes closely match the intended specifications.

Enhanced Collaboration: Physical prototypes facilitate communication between design teams, engineers, and stakeholders. Everyone can see and touch the product, making feedback more concrete.

Risk Reduction: Early detection of design flaws prevents expensive mistakes during manufacturing.

Material Versatility: Industrial 3D prototyping supports a wide range of materials, including plastics, metals, and composites, allowing for functional testing under real-world conditions.

For instance, a company developing a new consumer gadget can use 3D prototypes to test ergonomics and user interaction. This hands-on evaluation helps refine the product’s usability before finalizing the design.

How to Integrate Industrial 3D Prototyping into Your Workflow

Integrating industrial 3D prototyping into your design process requires careful planning and the right resources. Here are actionable steps to get started:

Define Your Objectives: Identify what you want to achieve with prototyping - whether it’s testing form, fit, function, or aesthetics.

Choose the Right Technology: Select a 3D printing method that suits your project needs. Common options include FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering).

Prepare Your Design Files: Use CAD software to create detailed 3D models. Ensure files are optimized for printing to avoid errors.

Select Materials Carefully: Match prototype materials to the intended use. For example, use durable plastics for functional parts or flexible materials for ergonomic testing.

Partner with Experts: Collaborate with experienced providers of 3d prototyping services to access advanced equipment and technical support.

Iterate and Test: Use prototypes to gather feedback, perform tests, and refine your design continuously.

By following these steps, you can maximize the benefits of industrial 3D prototyping and streamline your product development cycle.

High angle view of industrial 3D printer producing a prototype part in a manufacturing facility

Overcoming Common Challenges in Industrial 3D Prototyping

While industrial 3D prototyping offers many advantages, it also presents some challenges. Understanding these issues can help you avoid pitfalls and improve outcomes:

Material Limitations: Not all materials used in final products are suitable for 3D printing. Some prototypes may require post-processing or alternative fabrication methods.

Size Constraints: Large parts may need to be printed in sections and assembled, which can affect accuracy and strength.

Surface Finish: Depending on the printing technology, prototypes might have rough surfaces that require sanding or coating.

Cost Considerations: Although 3D prototyping is generally cost-effective, complex or high-volume projects can become expensive.

Design Complexity: Some intricate designs may be difficult to print without support structures, which add time and material costs.

To address these challenges, it is essential to work closely with your prototyping partner and leverage their expertise. They can recommend the best materials, printing techniques, and post-processing options to meet your project goals.

Future Trends in Industrial 3D Prototyping

The future of industrial 3D prototyping looks promising with continuous advancements in technology. Emerging trends include:

Multi-Material Printing: The ability to print with multiple materials simultaneously will enable more functional and realistic prototypes.

Faster Printing Speeds: Innovations in hardware and software will reduce production times, making rapid prototyping even more efficient.

Integration with AI and IoT: Smart prototyping systems will optimize print parameters and monitor quality in real-time.

Sustainability Focus: Eco-friendly materials and recycling methods will reduce the environmental impact of prototyping.

Mass Customization: Industrial 3D prototyping will support personalized products at scale, transforming manufacturing paradigms.

Staying informed about these trends will help businesses leverage industrial 3D prototyping to maintain a competitive edge.

Maximizing the Impact of Industrial 3D Prototyping on Your Designs

To fully benefit from industrial 3D prototyping, consider these best practices:

Start Early: Incorporate prototyping at the initial design stages to identify issues sooner.

Use Prototypes for Marketing: Physical models can be powerful tools for presentations, trade shows, and customer feedback.

Document Iterations: Keep detailed records of prototype versions to track improvements and decisions.

Train Your Team: Ensure designers and engineers understand 3D printing capabilities and limitations.

Evaluate ROI: Measure the impact of prototyping on development time, costs, and product quality to justify investment.

By adopting these strategies, you can enhance your industrial design process and deliver superior products to market faster.

Industrial 3D prototyping is revolutionizing how products are designed and developed. Its ability to create accurate, functional prototypes quickly and cost-effectively makes it an indispensable tool for modern industrial design. Whether you are refining a complex mechanical part or testing a new consumer product, leveraging industrial 3D prototyping can accelerate innovation and improve outcomes. Embrace this technology today to transform your design process and stay ahead in a competitive marketplace.

Comments